2025 Guide: How to Accelerate Product Development with Rapid Prototyping Injection Molding

In the fast-paced landscape of product development, companies are constantly seeking innovative ways to streamline their processes and bring ideas to market more efficiently. One powerful method that has emerged is rapid prototyping injection molding, a technique that significantly accelerates the prototyping phase of product creation. This process eliminates the lengthy iterations traditionally associated with design and manufacturing, allowing teams to transition from concept to a tangible product in record time. By leveraging advanced technologies and materials, rapid prototyping injection molding not only enhances the speed of development but also ensures precision and quality in the final product.

As the demand for quicker turnaround times and cost-effective solutions increases, embracing rapid prototyping injection molding can be a game-changer for organizations committed to remaining competitive. This guide outlines essential strategies and considerations for harnessing the power of this innovative molding technique. From understanding the basics of the process to exploring best practices for implementation, developers and engineers will gain valuable insights into optimizing their workflows. Whether launching a new product or iterating on an existing design, rapid prototyping injection molding may just be the key to unlocking new levels of efficiency and creativity in product development.

Understanding Rapid Prototyping Injection Molding Techniques

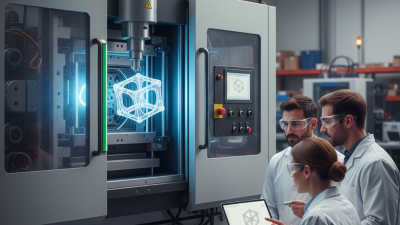

Rapid prototyping injection molding is a revolutionary technique that allows product developers to create prototypes quickly and efficiently. This method combines the speed of 3D printing with the durability of traditional injection molding, enabling designers to produce functional parts that can be tested and refined in real time. Understanding the intricacies of these techniques can significantly enhance the product development process, leading to quicker iterations and improved design accuracy.

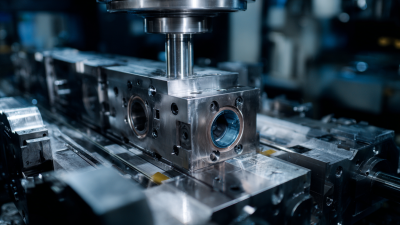

One crucial aspect of rapid prototyping injection molding is material selection. Choosing the right material can impact the prototype's performance, durability, and even manufacturability. Common materials used include thermoplastics and elastomers, each offering unique benefits. It is important to test different materials to find the best fit for your specific application. **Tips:** Always consider the end-use requirements of your prototype when selecting materials; this will help ensure that the prototype accurately reflects the final product's performance.

Moreover, design for manufacturability (DFM) should be prioritized during the prototyping phase. By designing parts that are easy to manufacture, you can minimize production costs and time. This includes considerations such as wall thickness, draft angles, and the avoidance of complex geometries that may complicate the molding process. **Tips:** Regularly collaborate with your prototyping team throughout the design process; their insights can help streamline production and reduce potential pitfalls in the molding phase.

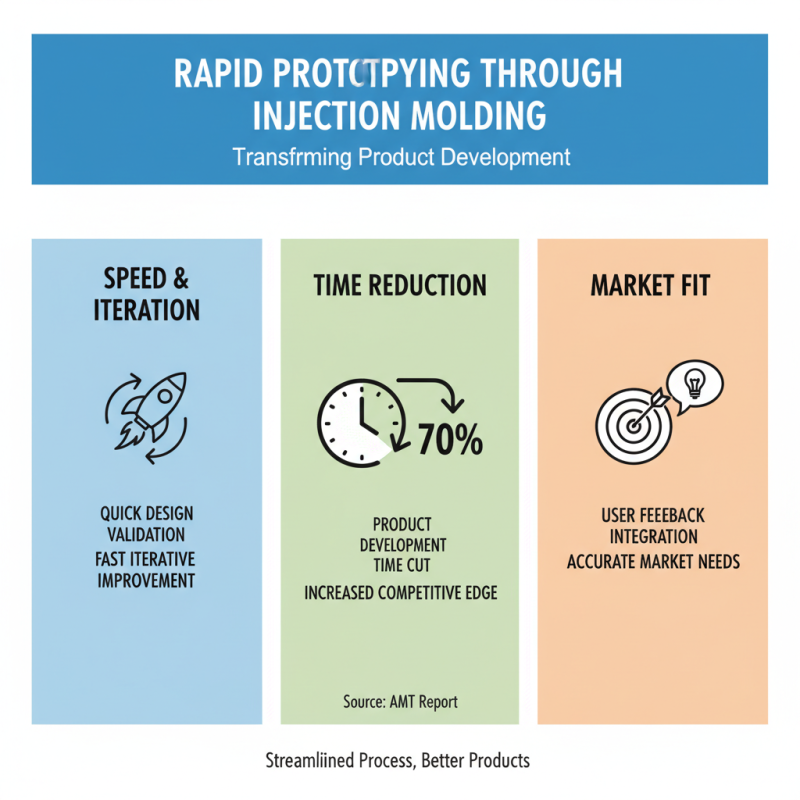

2025 Guide: Product Development Acceleration with Rapid Prototyping

This chart displays the time reduction in product development phases achieved through various rapid prototyping injection molding techniques over the years.

Key Benefits of Rapid Prototyping in Product Development

Rapid prototyping injection molding is revolutionizing the product development landscape, offering significant advantages that can streamline the entire process. One key benefit of this approach is the dramatic reduction in time-to-market. According to a study by the Product Development and Management Association (PDMA), companies that utilize rapid prototyping techniques can see development time reduced by up to 50%. This enables teams to iterate quickly on design concepts and test them in real-world scenarios, significantly enhancing the usability and market fit of the final product.

In addition to speeding up the process, rapid prototyping provides greater design flexibility. Engineers and designers can create multiple iterations without being heavily constrained by the costs associated with traditional manufacturing methods. For instance, a report by the American Society of Mechanical Engineers indicates that using rapid prototyping can lower prototyping costs by 30% to 40%. This financial efficiency allows for more creative exploration, ensuring that only the most viable ideas are pursued.

Tips: When integrating rapid prototyping into your development cycle, emphasize collaborative communication among stakeholders to gather feedback effectively. Additionally, consider investing in software that supports advanced modeling techniques; user-friendly tools can significantly enhance your team's ability to visualize and test ideas quickly. Finally, schedule regular review sessions to assess prototypes and make necessary adjustments before moving to production.

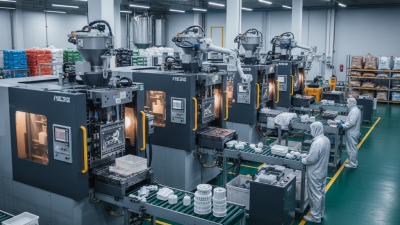

Step-by-Step Process of Rapid Prototyping Injection Molding

Rapid prototyping injection molding has emerged as a pivotal method for accelerating product development in today's fast-paced market. This process allows companies to create high-quality prototypes quickly, reducing the time from concept to production. According to a report by the Trade Association for the Plastics Industry, over 60% of manufacturers have reported a significant reduction in lead time when utilizing rapid prototyping techniques. This efficiency not only enhances innovation but also facilitates early testing, allowing designers and engineers to gather critical feedback before committing to full-scale manufacturing.

The step-by-step process of rapid prototyping injection molding typically involves several key phases. Initially, a detailed 3D model is generated using CAD software, allowing businesses to visualize the design and make necessary modifications. Following this, the rapid tooling process is initiated, wherein molds are created using additive manufacturing technologies like 3D printing. This approach can yield production-quality molds in a fraction of the time when compared to traditional methods. A survey by the American Society for Quality found that 70% of companies using this rapid approach reported lower costs associated with design changes, showcasing its ability to adapt quickly to market demands without incurring prohibitive expenses.

Best Practices for Effective Rapid Prototyping Implementation

Rapid prototyping through injection molding has transformed how products are developed, enabling teams to quickly validate designs and iterate based on real user feedback. According to a report from the Association for Manufacturing Technology, companies utilizing rapid prototyping can reduce their product development time by up to 70%, significantly enhancing their competitive edge. Effective implementation of rapid prototyping not only streamlines the development process but also ensures that products meet market needs more accurately.

To maximize the efficiency of rapid prototyping, consider the following best practices: First, invest in a robust design phase where collaboration between engineering and design teams can flourish. This collaboration brings valuable insights into manufacturability and user experience early in the process. Second, leverage digital twin technology to create accurate simulations of your prototypes, allowing for early identification of potential design flaws. According to a McKinsey report, firms using digital twins can save up to 30% in development costs by preemptively solving design issues.

Tip: Regularly gather feedback from stakeholders during the prototyping phase to make informed adjustments and refine designs effectively. Additionally, focus on strategically selecting materials that align with both your prototype's purpose and the final product's market demands, ensuring a smoother transition from prototype to production. With these strategies, businesses can enhance their product development efforts and stay ahead of the competition.

Future Trends in Rapid Prototyping and Injection Molding Technologies

The future of rapid prototyping and injection molding technologies is poised for transformative advancements that promise to enhance efficiency and creativity in product development. One key trend is the integration of artificial intelligence and machine learning into the design and prototyping processes. These technologies facilitate better simulation of product performance and streamline iterations, allowing designers to quickly assess and optimize prototypes before moving into production. This not only saves time but also reduces material waste, which is increasingly vital in a world focused on sustainability.

Another important trend is the rising adoption of hybrid manufacturing techniques that combine traditional injection molding with additive manufacturing. This approach enables manufacturers to leverage the strengths of both processes, resulting in complex geometries and lighter components without sacrificing durability. Additionally, advancements in materials science are leading to the development of new polymers that enhance the performance and versatility of prototypes. As these technologies evolve, they will not only accelerate the product development cycle but also empower businesses to innovate more boldly and respond rapidly to market demands.

2025 Guide: How to Accelerate Product Development with Rapid Prototyping Injection Molding - Future Trends in Rapid Prototyping and Injection Molding Technologies

| Dimension | Trend | Impact on Product Development | Future Prospects |

|---|---|---|---|

| Materials Used | Biodegradable Plastics | Promotes sustainability in product design. | Increasing adoption by eco-conscious companies. |

| Speed of Prototyping | On-Demand Prototyping | Reduces time to market significantly. | Potential for real-time adjustments based on feedback. |

| Design Complexity | Multi-material Injection Molding | Enables complex geometries and functionalities. | Opens new possibilities for innovative product features. |

| Cost Efficiency | Automated Production Processes | Reduces labor costs and production errors. | Long-term savings in mass production. |

| Customization | User-Centered Design Approaches | Enhances user satisfaction by addressing specific needs. | Increasing demand for personalized products. |

Related Posts

-

How to Use Rapid Prototyping with Injection Molding for Fast Product Development

-

How to Maximize Efficiency in Precision Injection Molding Processes

-

10 Best Injection Molding Techniques for Maximizing Efficiency in Production

-

Understanding the Impact of Molding Precision on Sustainable Manufacturing Practices

-

Understanding US Injection Molding: Key Statistics and Trends Shaping the Industry in 2023

-

Exploring the Future of US Injection Molding: Innovations and Industry Trends