How to Achieve High Molding Precision in Manufacturing?

Achieving high molding precision in manufacturing is a critical goal for many industries. Dr. Emily Chen, an expert in molding technology, emphasizes, "Precision molds lead to better quality products." This statement reflects the importance of accurate molding in creating components that meet rigorous standards.

Molding precision involves not just the initial design but also the choice of materials and techniques. A small error in measurements can lead to significant flaws in the final product. Manufacturers must continually assess their processes. They should look for areas to improve. While advancements in technology have helped, challenges remain. Balancing cost and precision is an ongoing struggle.

In pursuit of high molding precision, relying solely on new technologies is not enough. Skilled workers and their experience matter equally. However, there are still gaps in the workforce's training. This can hinder progress and affect the overall quality. Constant reflection on these aspects is essential to push the boundaries of what’s possible in molding precision.

Understanding Molding Precision in Manufacturing Processes

Achieving high molding precision is crucial in manufacturing. Understanding molding precision is the first step towards excellence. It involves controlling various factors during the molding process. Temperature, pressure, and material choice all play significant roles. Each adjustment can lead to variations in the final product.

Precision is not only about exact measurements. It also requires an understanding of potential flaws. For instance, minor defects can arise from material shrinkage or uneven cooling. These imperfections impact product quality and performance. Regular assessments of the process can reveal areas for improvement.

Manufacturers often face challenges in maintaining consistent precision. Equipment wear and tear can lead to inconsistencies. Operators must be trained to spot and address these issues. Continued education and reflection on past molds can lead to advancements. Identifying these pitfalls is essential for achieving a higher level of quality in important projects.

How to Achieve High Molding Precision in Manufacturing?

This chart illustrates the percentage of molding precision in various manufacturing processes over a six-month period. The aim is to provide insight into the improvement of precision levels and the effectiveness of different techniques utilized in molding.

Key Factors Affecting Molding Precision in Manufacturing

Achieving high molding precision in manufacturing relies heavily on several key factors. First, the choice of material plays a crucial role. According to a report by the American Society for Testing and Materials, over 75% of manufacturing defects are linked to material properties. Using high-quality polymers ensures better flow and less shrinkage. However, it’s essential to balance cost and quality. Cheaper materials may lead to higher waste and more defects.

Machine calibration is another critical factor. Regular checks and calibrations can prevent dimensional inaccuracies. A study by the Society of Manufacturing Engineers found that 60% of precision issues stem from misaligned machinery. Operators must be well-trained. Even highly advanced machines can produce flawed parts if not operated correctly. It’s also vital to implement robust quality control measures. However, human error in inspections can introduce variability, sometimes leading to overlooked defects.

Environmental conditions can also influence molding precision. Temperature and humidity levels impact material behavior during the molding process. A study from the International Journal of Advanced Manufacturing Technology demonstrated that fluctuations in these conditions resulted in a 15% increase in dimensional variability. Companies need to monitor their production environments closely. Neglecting this can lead to significant repercussions on the final product quality, revealing the importance of consistent production conditions.

How to Achieve High Molding Precision in Manufacturing? - Key Factors Affecting Molding Precision in Manufacturing

| Factor | Description | Impact Level (1-5) |

|---|---|---|

| Material Quality | The physical properties of the materials used directly affect the precision of molds. | 5 |

| Mold Design | A well-thought-out mold design optimizes the production process and reduces defects. | 5 |

| Machinery Calibration | Properly calibrated machinery ensures accurate and consistent molding results. | 4 |

| Temperature Control | Maintaining optimal temperature during the molding process affects material flow and solidification. | 4 |

| Pressure Parameters | The correct application of pressure can lead to better filling and fewer defects. | 5 |

| Operator Skill | The experience and skill of the operators play a significant role in achieving precision. | 3 |

| Process Monitoring | Regular monitoring and adjustments during production can identify and rectify issues promptly. | 4 |

Techniques for Enhancing Molding Precision in Production

Achieving high molding precision requires a deep understanding of various techniques. One key method is utilizing advanced CNC machining. According to a report by the International Journal of Advanced Manufacturing Technology, up to 80% of molding errors stem from insufficient machining accuracy. Implementing CNC technology can significantly reduce dimensional variability.

Temperature control during the molding process is crucial. Maintaining optimal temperatures can minimize material shrinkage, which affects precision. Research shows that molds need to be kept at a consistent temperature to ensure uniform material flow. Fluctuations can lead to defects, disrupting production schedules. It's a common oversight that can be easily mitigated with proper monitoring tools.

Additionally, regular maintenance of molding equipment is often overlooked. A survey by the Manufacturing Institute noted that 30% of manufacturers reported precision issues due to aging equipment. Investing in routine checks and upgrades can greatly enhance molding accuracy. However, many companies still hesitate to allocate necessary resources to this aspect, often leading to higher costs in the long run.

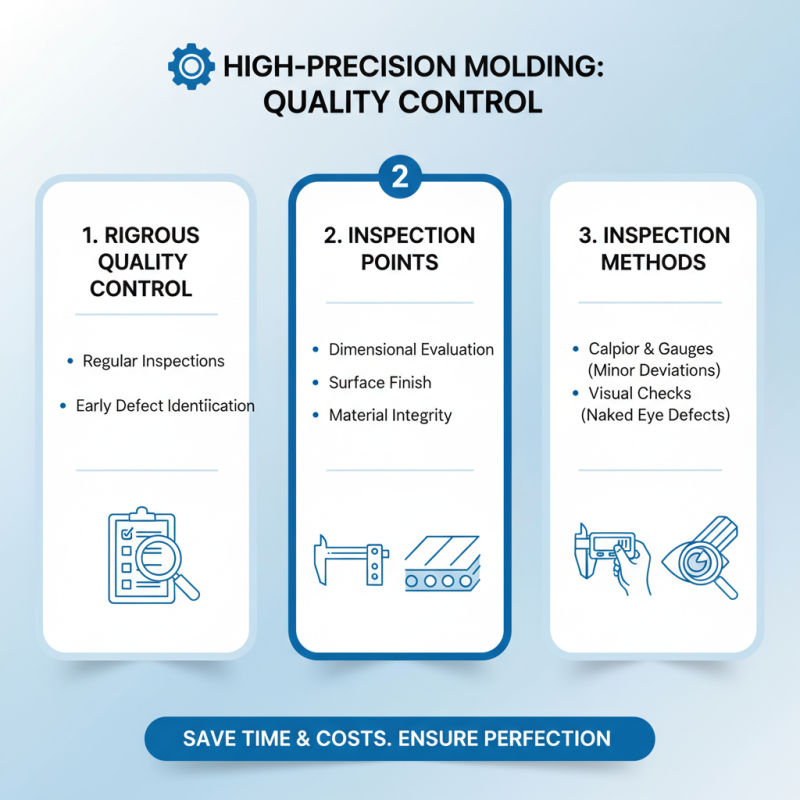

Quality Control Measures for High Precision in Molding

Achieving high precision in molding requires rigorous quality control measures. Regular inspections play a vital role in identifying defects early. These checks should include evaluating dimensions, surface finish, and material integrity. Instruments like calipers and gauges help detect even minor deviations. It is common to overlook the importance of visual inspections. However, many defects are visible to the naked eye, and catching them early can save time and costs.

Another crucial aspect is process monitoring. Tracking variables like temperature, pressure, and timing can significantly impact molding quality. Small fluctuations often lead to larger issues. For instance, improper cooling can cause warping, while inconsistent pressure can result in voids. Manufacturing teams should log these variables diligently. This data can highlight patterns and detect anomalies.

Finally, fostering a culture of feedback is essential. Employees should feel comfortable reporting observations and suggesting improvements. Relying solely on standard procedures can mask underlying problems. Regular team meetings to discuss challenges and share experiences can lead to innovative solutions. Embracing imperfection can drive continuous improvement in molding processes.

Future Trends in Molding Precision Technologies

The landscape of molding precision technologies is evolving rapidly. Industry reports indicate that advancements in automation and real-time monitoring can boost precision levels by up to 30%. The integration of machine learning allows for predictive maintenance, which reduces downtime and maintains consistent quality.

New materials, such as advanced composites, are gaining traction. These materials offer enhanced durability and can withstand more demanding applications. However, they often require new processing techniques, which can introduce variability in the molding process. Balancing these variables remains a challenge.

The rise of additive manufacturing further complicates the scenario. While it presents opportunities for creating complex geometries, integrating this technology with traditional molding methods is still an unresolved problem. Some studies suggest that achieving a seamless transition will take years of research and development. The need for precise tolerance is more critical than ever, prompting manufacturers to rethink their strategies.

Related Posts

-

Understanding the Impact of Molding Precision on Sustainable Manufacturing Practices

-

Ultimate Guide to Achieving High Molding Precision in Manufacturing

-

Ultimate Guide to Precision Injection Molding for Global Buyers in 2023

-

What is Precision Molding and How Does it Impact Manufacturing Efficiency

-

Top Molding Precision Techniques for Enhanced Product Quality?

-

The Future of Injection Mold Making Innovations Driving Efficiency and Cost Savings in Manufacturing