How to Advantageously Use Contract Injection Molding?

In the world of manufacturing, contract injection molding plays a crucial role. This technique allows companies to create complex plastic parts efficiently. It integrates design, production, and quality control into one seamless process. Many businesses benefit from contract injection molding due to its cost-effectiveness and scalability.

However, some companies struggle to maximize its potential. They may overlook the importance of selecting the right materials. Choosing inferior materials can lead to product failures. Additionally, effective communication with the contract manufacturer is essential. Misunderstandings can result in wasted resources and time.

Furthermore, not all designs are compatible with this method. Designers must consider mold design and cooling times. Failing to do so can create weak spots in the final product. Navigating these challenges requires a reflective approach. A clear understanding of contract injection molding can lead to better outcomes. Investing time in these areas can enhance overall efficiency and product quality.

Understanding Contract Injection Molding: A Comprehensive Overview

Contract injection molding is a strategic process in manufacturing. It allows businesses to produce plastic parts efficiently and cost-effectively. This method involves a contract manufacturer who specializes in injection molding. They take on production responsibilities for clients who may lack the resources or technology.

Understanding the nuances of contract injection molding is crucial. Companies can save on overhead costs while accessing advanced machinery. A well-executed project often leads to high-quality products at scale. However, choosing the right partner requires careful thought. Miscommunication can lead to delays or defects, creating setbacks.

It's essential to evaluate potential partners thoroughly. Look for expertise and a proven track record. Transparency in pricing and timelines is vital. Set clear expectations from the start to avoid issues down the line. While contract injection molding offers numerous benefits, it also demands diligence and active involvement to achieve the desired outcomes.

How to Advantageously Use Contract Injection Molding?

| Material Type | Cycle Time (seconds) | Production Rate (units/hour) | Typical Applications | Cost per Unit ($) |

|---|---|---|---|---|

| ABS Plastic | 25 | 120 | Consumer Electronics | 0.50 |

| Polypropylene | 30 | 100 | Packaging, Automotive | 0.40 |

| Polycarbonate | 35 | 80 | Optical Components | 1.20 |

| Nylon | 40 | 70 | Industrial Applications | 0.80 |

| Polystyrene | 20 | 150 | Toys, Household Items | 0.30 |

Key Benefits of Contract Injection Molding for Manufacturing Efficiency

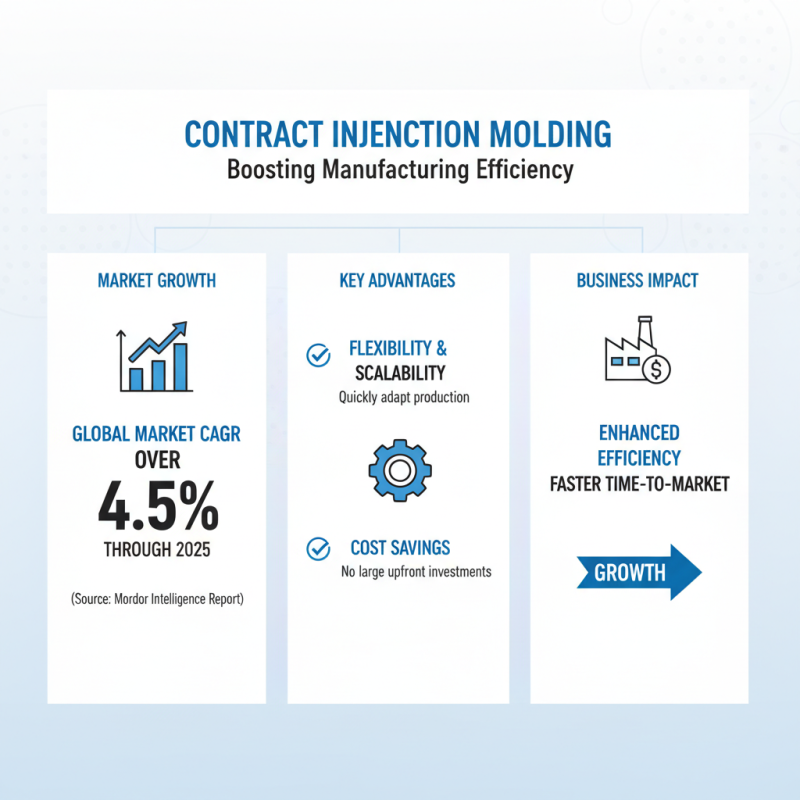

Contract injection molding has emerged as a key player in enhancing manufacturing efficiency. According to a recent report by Mordor Intelligence, the global contract injection molding market is projected to grow at a CAGR of over 4.5% through 2025. This growth is driven by the flexibility and cost savings offered by contract manufacturers. Companies can quickly scale production without large upfront investments, which is a significant advantage.

One of the key benefits of contract injection molding is reduced lead times. Manufacturers that utilize these services can expect quicker turnaround times. This is crucial in industries where time-to-market is essential. Furthermore, it allows companies to adapt to market changes without the burden of maintaining large equipment. However, choosing the right contract manufacturer is critical. Compatibility issues or quality inconsistencies can create challenges.

Another benefit lies in the access to advanced technology. Many contract manufacturers invest heavily in innovative equipment. This provides clients access to high-quality production methods without significant capital expenditures. However, not all providers might meet the latest standards consistently. Companies need to verify capabilities through audits and discussions. Understanding these factors can dramatically influence the success of your manufacturing operations.

Factors Affecting Cost-Effectiveness in Contract Injection Molding

Cost-effectiveness in contract injection molding is influenced by several key factors. Material choice plays a vital role. The type of plastic chosen impacts both initial and long-term costs. Some materials may be cheaper upfront but lead to higher waste rates or longer cycle times. Selecting the right resin requires careful consideration of its properties and performance.

The design of the mold is another crucial aspect. A well-designed mold can reduce production time and lower the number of defective parts. This not only improves efficiency but also affects overall project costs. However, complex designs may require higher initial investments. It is essential to strike a balance between complexity and functionality.

Labor costs are also significant. Experienced operators can enhance production quality. On the flip side, inexperienced teams might lead to costly mistakes. Training and skilled labor can add to expenses. Still, investing in personnel can yield better outcomes in the long run. Each of these factors must be evaluated thoughtfully to ensure a beneficial contract injection molding strategy.

Cost-Effectiveness Factors in Contract Injection Molding

Quality Control Metrics in Contract Injection Molding Processes

In the realm of contract injection molding, quality control is paramount. It significantly impacts product performance and manufacturing efficiency. According to a report by the Society of Plastics Engineers, about 25% of injection-molded parts fail to meet design specifications. This highlights the need for stringent quality metrics.

Critical metrics include cycle time, reject rates, and dimensional accuracy. Cycle time should be continuously monitored. Industry benchmarks indicate an ideal cycle time reduction of 10-15% can drastically enhance productivity. Monitoring reject rates is essential. A high reject rate can indicate process inefficiencies, often leading to increased costs. In some cases, reports show reject rates can exceed 20%, prompting a reevaluation of quality control procedures.

Dimensional accuracy is another vital factor. It ensures that parts fit together as designed. A tolerance variance of only 0.5mm can lead to assembly issues. Regular audits and process validations should be a priority. The lack of consistent quality checks can result in discrepancies, complicating final assembly processes. By focusing on these metrics, manufacturers can improve their quality assurance in contract injection molding and enhance overall operational efficiency.

Recent Trends and Innovations in Contract Injection Molding Industry

The contract injection molding industry is witnessing exciting innovations. New materials are emerging, enhancing durability and flexibility. Biodegradable plastics are gaining traction, appealing to eco-conscious manufacturers. This shift is not just green; it presents challenges in processing techniques. Traditional methods may need adjustments to handle these materials effectively.

Automation is another trend reshaping the industry. Robots are increasingly being used to streamline production. They improve precision and reduce labor costs. However, the transition isn’t always smooth. Companies may struggle with the integration of robotic systems into existing workflows. Training employees to work alongside robots can also be daunting.

Collaboration is crucial in this evolving landscape. Companies need to work closely with mold designers and engineers. This ensures that product specifications align with manufacturing capabilities. Miscommunications can lead to costly errors. The demands of clients are continually changing, which requires companies to be adaptable.

Experimenting with new ideas while reflecting on past mistakes will lead to better outcomes.

Related Posts

-

Unlocking Efficiency: The Key Benefits of Contract Injection Molding for Manufacturing Success

-

Understanding US Injection Molding: Key Statistics and Trends Shaping the Industry in 2023

-

How to Maximize Efficiency in Precision Injection Molding Processes

-

Exploring Market Trends and Innovations in Injection Molding Contract Manufacturing for 2024

-

How to Master Contract Injection Molding for Your 2025 Production Needs

-

2025 Top Innovations in Injection Molding Prototyping for Product Development