10 Best Injection Molding Techniques for Maximizing Efficiency in Production

Injection molding is a highly versatile manufacturing process widely utilized in various industries to produce a vast array of plastic parts and components. As the demand for efficiency and cost-effectiveness continues to rise, manufacturers are increasingly compelled to adopt innovative techniques that maximize productivity without sacrificing quality. In this context, understanding the best injection molding techniques becomes paramount for companies aiming to enhance their operational effectiveness and remain competitive in the market.

In this article, we will explore the ten best injection molding techniques that can significantly improve production efficiency. From optimizing machine settings to employing advanced materials and automation, these strategies not only streamline the manufacturing process but also minimize waste and reduce cycle times. By implementing these techniques, manufacturers can achieve faster turnaround times and lower production costs, ultimately driving profitability and customer satisfaction. Whether you are new to injection molding or looking to refine your existing practices, this guide will provide valuable insights to elevate your production capabilities.

Overview of Injection Molding Techniques for Efficient Production

Injection molding is a highly efficient manufacturing process widely used to produce plastic components. Current industry reports indicate that about 30% of all plastic products are created through injection molding, underscoring its importance in modern production strategies. Key techniques such as multi-component molding and gas-assisted injection molding have emerged as optimizations to enhance the production process. Multi-component molding allows for the creation of complex parts in a single cycle, significantly cutting down on production time, while gas-assisted techniques reduce material usage and improve surface finish, ultimately leading to lower costs.

Moreover, advanced methods like low-pressure injection molding and 3D injection molding are transforming production capabilities. According to a recent study by the Injection Molding Association, these methods can increase efficiency by up to 25% when combined with automation technologies. Low-pressure injection molding minimizes stresses on the material, which can lead to higher quality finishes and a reduction in defects. The adoption of smart manufacturing technologies in conjunction with these injection molding techniques enables manufacturers to achieve not only efficiency but also real-time monitoring of production processes, driving further improvements in operational efficacy.

10 Best Injection Molding Techniques for Maximizing Efficiency in Production

This chart illustrates the various injection molding techniques and their potential efficiency improvements in production. Each technique contributes differently, showcasing areas where companies can focus to enhance their production efficiency.

Key Considerations in Choosing Injection Molding Techniques

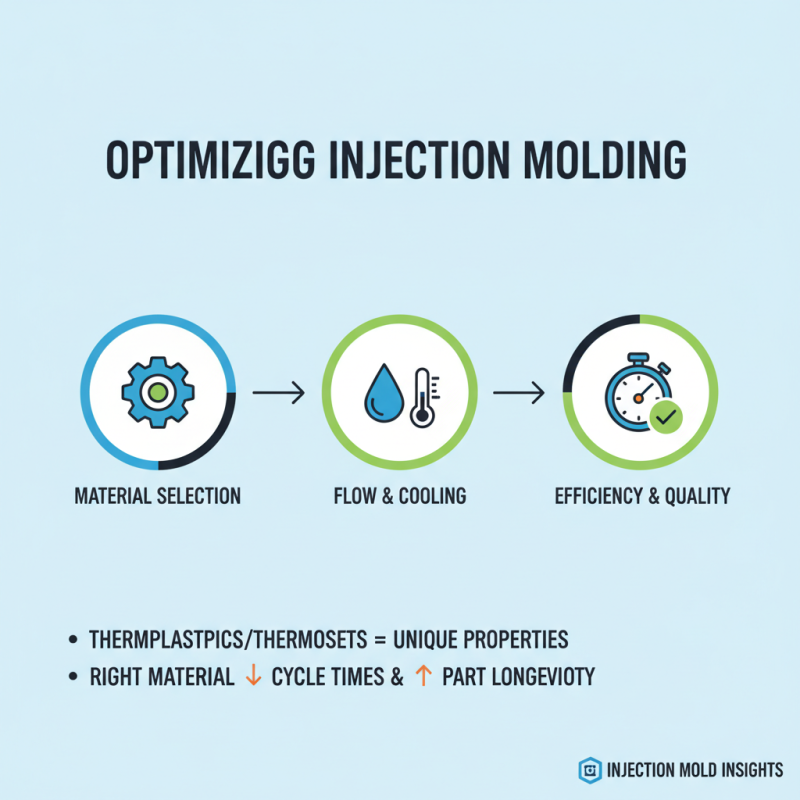

When choosing injection molding techniques, several key considerations can significantly influence production efficiency and overall product quality. First and foremost, the material selection plays a crucial role. Different thermoplastics and thermosetting plastics have unique properties that can affect flow rates and cooling times during the molding process. Selecting the right material not only enhances the longevity of the molded parts but also can streamline the production process by reducing cycle times.

Another critical aspect is the design of the mold itself. A well-optimized mold design can lower manufacturing costs and minimize waste. Features like adequate draft angles, uniform wall thickness, and strategically placed vents help ensure smooth material flow and efficient cooling. Additionally, investing in advanced mold technologies, such as hot runner systems, can reduce material usage and decrease cycle times, which are essential factors for maximizing efficiency in production. Careful consideration of these factors will lead to better decision-making, ultimately ensuring that the chosen injection molding technique aligns with business objectives and production goals.

Top Injection Molding Techniques for Cost Reduction and Time Savings

When it comes to injection molding, maximizing efficiency while minimizing costs is crucial for competitive manufacturing. Adopting effective techniques can result in significant time savings and reduced expenses in production. Utilizing advanced mold designs, for instance, can optimize the flow of materials and decrease cycle times, thereby enhancing productivity while controlling costs.

Tips: One approach is to implement a hot runner system, which can eliminate the need for runners and sprues, saving on material waste and expediting the injection process. Additionally, investing in simulation software to analyze the mold filling process can help identify issues before production starts, reducing modifications and delays later on.

Another technique to consider is the use of optimized cycle timing. By coordinating the cooling time with the injection process, manufacturers can ensure that parts are ejected at their optimal strength, further refining the entire workflow. Furthermore, regular maintenance of machines and molds can prevent breakdowns and extend equipment life, ultimately leading to lower operational costs and improved efficiency.

Innovative Technologies Enhancing Injection Molding Efficiency

Innovative technologies in the field of injection molding play a pivotal role in enhancing production efficiency. As per a report from MarketsandMarkets, the injection molding market is projected to reach USD 336.72 billion by 2026, demonstrating a compound annual growth rate (CAGR) of 4.4% from 2021. This growth is driven by advancements like automated production systems, which reduce cycle times and labor costs. By implementing robotics and AI-driven processes in injection molding operations, manufacturers can achieve precision and speed that were previously unattainable, optimizing both resource allocation and output.

Additionally, the integration of smart sensors and IoT technology allows for real-time monitoring and predictive maintenance of machines. According to a study from the International Journal of Advanced Manufacturing Technology, factories that adopt smart-injection molding technologies experienced a 25% increase in efficiency and a significant reduction in downtime. These innovations not only streamline production but also minimize material waste and energy consumption, leading to more sustainable practices within the industry. As manufacturers embrace these technological advancements, the injection molding landscape is set for a monumental shift toward greater efficiency and productivity.

Comparison of Traditional vs. Advanced Injection Molding Methods

The comparison between traditional and advanced injection molding methods reveals significant advancements in efficiency and sustainability. Traditional injection molding techniques have long dominated the manufacturing landscape, relying on established processes that often prioritize speed and volume. However, as industries seek to align with environmental standards, innovations such as low-pressure injection molding are emerging. This sustainable approach not only reduces energy consumption but also minimizes waste, aligning production methods with modern eco-conscious practices.

In contrast, advanced injection molding techniques leverage cutting-edge technologies like servo-electric drives and integrated coating processes. These innovations enhance precision and adaptability, enabling manufacturers to respond more swiftly to market demands. Furthermore, the incorporation of additive manufacturing into the molding process has opened new avenues for rapid prototyping and customization, allowing for better design validation before mass production. As manufacturers continue to explore the potential of these advanced methodologies, the collaboration between traditional practices and new technologies will shape the future of production efficiency.

Related Posts

-

Exploring Injection Moulding Process Innovations at the 138th China Import and Export Fair 2025

-

Maximizing Efficiency: Key Advantages of Injection Molding in Modern Manufacturing

-

Why Injection Molding Prototyping is Essential for Product Development Success

-

Ultimate Guide to Precision Injection Molding for Global Buyers in 2023

-

Mastering Injection Molding Design: Tips for Reducing Production Costs and Enhancing Efficiency

-

Injection Mold Making: A Comparative Analysis of Techniques and Materials for Optimal Production