How to Choose the Right Manufacturing Technology for Your Business in 2025

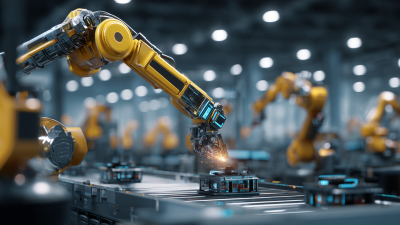

As businesses prepare for the technological landscape of 2025, selecting the right manufacturing technology becomes critical for enhancing operational efficiency and maintaining competitive advantage. According to the latest report by the International Federation of Robotics, global investment in industrial robots is expected to reach $26 billion by 2025, illustrating a significant shift towards automation in the manufacturing sector. This data underscores the importance of harnessing advanced manufacturing technologies that not only optimize production processes but also promote sustainability and adaptability in rapidly changing markets.

Industry expert Dr. Emily Schwartz, a leading authority on manufacturing innovation, emphasizes the necessity for businesses to "embrace transformative manufacturing technologies to stay ahead of the curve and meet evolving consumer demands." Her perspective highlights the pivotal role that technologies such as additive manufacturing, AI-driven analytics, and smart factories will play in shaping the future of production. As companies navigate this critical decision-making process, understanding the landscape of available manufacturing technologies will be essential for fostering growth, enhancing productivity, and achieving long-term success.

Identifying Key Manufacturing Needs for Your Business in 2025

In 2025, manufacturing needs will significantly evolve, and businesses must proactively identify and address these changes to stay competitive. A recent report from the International Federation of Robotics predicts that the adoption of automation technologies will rise by 25% in the manufacturing sector, driven by the need for efficiency and precision. Companies need to assess their current production processes and identify areas where automation can enhance productivity. Understanding the specific requirements, such as speed, scalability, and flexibility, is crucial for selecting the right technology.

Furthermore, sustainability will become a pivotal factor in manufacturing decisions. According to the Ellen MacArthur Foundation, transitioning to circular manufacturing practices can reduce costs by up to 30% while meeting consumer demand for eco-friendly products. Businesses should evaluate their supply chains and manufacturing workflows to identify opportunities for incorporating sustainable technologies, such as energy-efficient machinery and waste reduction systems. By aligning technology choices with both operational efficiency and sustainability goals, companies will be well-positioned to thrive in the evolving manufacturing landscape of 2025.

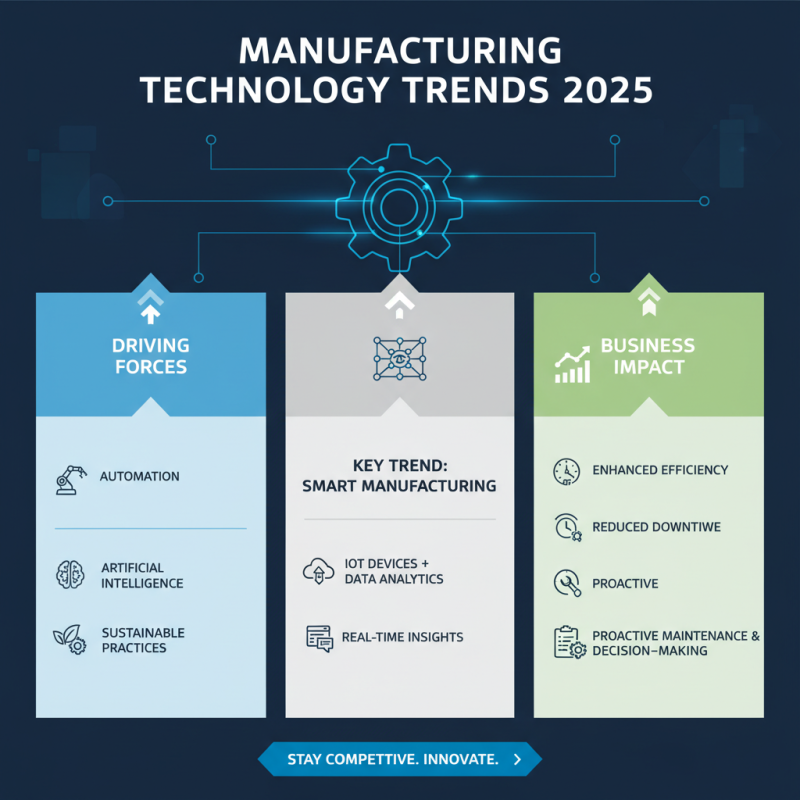

Evaluating Current Trends in Manufacturing Technology

As we look towards 2025, the landscape of manufacturing technology is evolving rapidly, driven by advancements in automation, artificial intelligence, and sustainable practices. Evaluating current trends in manufacturing technology becomes critical for businesses aiming to remain competitive. One significant trend is the increasing integration of smart manufacturing solutions, which leverage IoT devices and data analytics to enhance production efficiency and reduce downtime. This shift allows businesses to gain real-time insights into their operations, facilitating more informed decision-making and proactive maintenance strategies.

Another notable trend is the emphasis on sustainability and eco-friendly manufacturing processes. Companies are now prioritizing technologies that minimize waste and energy consumption, reflecting a growing consumer demand for environmentally responsible products. This shift not only helps in reducing the carbon footprint but also positions businesses favorably in a market where sustainability is becoming increasingly important. In 2025, organizations will need to evaluate these trends closely, considering how adopting such technologies can lead to long-term benefits and alignment with both consumer expectations and regulatory requirements.

Assessing Costs vs. Benefits of Different Technologies

As businesses gear up for 2025, selecting the right manufacturing technology has become increasingly crucial. One of the key considerations in this decision-making process is the assessment of costs versus benefits. A recent report by the International Federation of Robotics indicates that companies adopting advanced robotics can achieve up to a 40% increase in productivity while simultaneously reducing operational costs by roughly 20%. This data underscores the significance of analyzing not just the upfront investment in technology but also the long-term returns it can generate.

When assessing potential technologies, it is beneficial to conduct a thorough cost-benefit analysis. Consider factors such as training requirements, maintenance costs, and potential downtime. For example, a manufacturing operation that implements IoT sensors may initially face high setup costs; however, the potential for predictive maintenance can lead to a reduction in unexpected downtime by up to 30%, translating into substantial savings. Additionally, it's essential to evaluate the scalability of the technology to ensure it can grow with your business needs.

Tips:

- Create a detailed spreadsheet to compare the initial investment and projected returns for each technology alternative.

- Consider piloting a technology on a small scale to evaluate its practical benefits before making a full-scale investment.

- Engage with industry experts or consultants who can provide insights tailored to your specific manufacturing environment and future goals.

Understanding Integration with Existing Systems and Processes

When selecting the right manufacturing technology for your business in 2025, understanding how these new systems will integrate with your existing operations is crucial. A seamless integration process can minimize downtime and disruptions, enabling a smoother transition while maximizing the efficiencies of both new and current technologies. Begin by assessing the compatibility of new manufacturing solutions with your existing machinery, software, and workflows. This evaluation will help identify potential challenges ahead of time and guide your decision-making process more effectively.

Furthermore, consider the scalability of the new technology in relation to your current systems. As businesses evolve, it's vital to adopt solutions that not only meet present needs but can also adapt to future demands. Engaging with stakeholders across various departments will provide insights into how a new technology can enhance or alter established processes. This collaborative approach ensures that all operational areas are aligned, paving the way for enhanced productivity and improved overall performance in your manufacturing strategy.

Planning for Future Scalability and Adaptability in Manufacturing

In 2025, selecting the right manufacturing technology hinges significantly on

future scalability and

adaptability. As industries evolve,

businesses must choose technologies that not only meet current demands but also allow for

growth and change over time. This means considering modular systems that can be upgraded or

expanded without extensive reinvestments, ensuring that your manufacturing processes can keep

pace with market developments and innovations.

Tips for scalability include investing in

automation systems that can easily

integrate with existing workflows and adapt to varying production volumes. Look for solutions

that offer flexible configurations, allowing you to reassign resources efficiently as demand shifts.

Another critical aspect is workforce training; ensuring your team is equipped to handle new technologies

will minimize disruptions when adapting to changes. Encourage a culture of

continuous learning to foster

adaptability within your organization.

In terms of adaptability, prioritize technologies that offer

data-driven insights. Systems that provide

real-time analytics can help your business respond swiftly to market fluctuations and optimize

operations. Additionally, consider technology partnerships that provide support and updates,

keeping your systems current and aligned with industry standards. Embracing a mindset of

agile manufacturing will prepare your

business for the uncertainties of the future, ensuring resilience in a rapidly changing landscape.

Related Posts

-

How to Leverage Manufacturing Technology for Enhanced Production Efficiency

-

How to Revolutionize Your Production Process with Advanced Manufacturing Technology

-

Revolutionizing Manufacturing Technology with Smart Factories and AI Innovations

-

Exploring Injection Moulding Process Innovations at the 138th China Import and Export Fair 2025

-

Why Rapid Prototyping Injection Molding is Essential for Product Development

-

2025 Top Trends in Mold Making: Innovations Driving $14 Billion Industry Growth