Why Injection Molding Prototyping is Essential for Product Development Success

In the fast-paced world of product development, the urgency to transform innovative ideas into market-ready solutions is paramount. An increasing number of companies are turning to injection molding prototyping as a critical step in this process. According to a recent report by Allied Market Research, the global injection molding market is projected to reach $441.9 billion by 2027, highlighting the growing reliance on this technology. The significance of injection molding prototyping lies not only in its ability to produce high-quality, precise prototypes quickly but also in its capacity to reduce time and costs associated with tooling and production.

Industry expert Dr. Emily Chen, a leading authority in injection molding technologies, emphasizes the importance of this approach: "Injection molding prototyping enables companies to identify design flaws early and refine their products efficiently, ultimately leading to increased market competitiveness." As organizations strive for excellence, incorporating injection molding prototyping into their product development strategy has become essential. With the ability to iterate designs swiftly and accurately, businesses can enhance their development cycles and ensure that their final products resonate with consumer demand.

In conclusion, the integration of injection molding prototyping is no longer just an option but a necessity for companies aiming to innovate and succeed in today's competitive landscape. By embracing this advanced technique, businesses can significantly improve their product outcomes and maintain a strong foothold in the market.

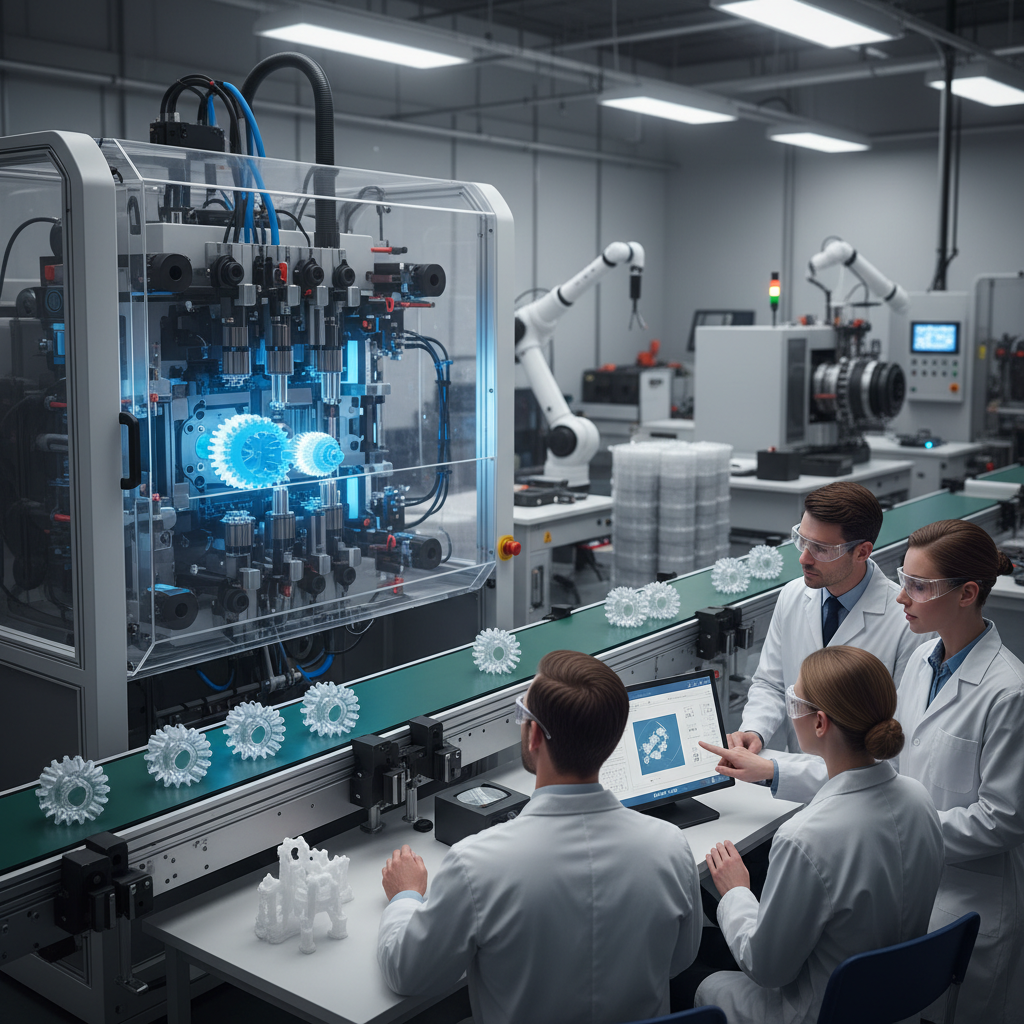

The Role of Injection Molding Prototyping in Accelerating Product Design

Injection molding prototyping plays a crucial role in accelerating product design, making it an essential component for successful product development. Recent reports indicate that leveraging advanced technologies like 3D printed injection molds can reduce the traditional multi-step manufacturing process significantly. For instance, companies that adopt 3D printing for mold creation have observed time savings of up to 75%, allowing for faster iteration and modifications during the design phase. This rapid prototyping not only streamlines the production timeline but also facilitates quicker responses to market demands.

Furthermore, the integration of generative AI alongside injection molding techniques has the potential to revolutionize product design workflows. While generative AI can enhance creativity and efficiency, it is the expertise of seasoned design professionals that ensures the innovative ideas generated are viable. Data suggests that combining human intelligence with AI capabilities can reduce the overall product design life cycle by an estimated 30%. Such advancements are particularly valuable in industries like medical device manufacturing, where speed is critical. Implementing freeform injection molding processes helps firms achieve faster time-to-market for complex devices, further solidifying the importance of prototyping in enhancing product development success.

Key Advantages of Using Injection Molding for Prototypes in Development

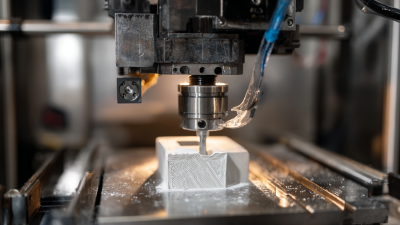

Injection molding prototyping has become a cornerstone in modern product development, offering several key advantages that streamline the process. One major benefit is the ability to produce highly accurate and consistent prototypes. Unlike other methods, injection molding allows manufacturers to achieve close tolerances and repeatable results, which is essential for testing the functional aspects of a design. This precision enables developers to identify design flaws early, saving time and resources in the long run.

Another significant advantage of using injection molding for prototypes is the material versatility it provides. This process supports a wide range of thermoplastics and thermosetting materials, allowing teams to choose options that closely resemble the final product’s look and feel. Consequently, the prototypes not only serve as a means for evaluation but also offer insights into how the product will perform in real-world applications. This capability fosters better decision-making during the development phase, ultimately contributing to a more successful product launch.

How Injection Molding Prototyping Enhances Material Selection and Testing

Injection molding prototyping plays a crucial role in enhancing material selection and testing during the product development process. By producing initial prototypes that closely mimic the final product, designers and engineers can evaluate the feasibility of different materials under real-world conditions. This evaluation is essential, as it enables teams to understand how variations in material composition can affect the product’s performance, durability, and cost-effectiveness. By experimenting with various materials, companies can identify the best options that meet both functional and aesthetic requirements.

Moreover, injection molding prototyping facilitates rigorous testing and validation, allowing for a comprehensive analysis of material properties. This process not only identifies potential weaknesses but also reveals opportunities for innovation in material design. It ensures that the selected materials align with the project’s goals, leading to improved product quality and a reduced risk of failure in the market. The iterative nature of prototyping allows for continuous refinement, where feedback from physical prototypes can guide material selection in real-time, making the final product more robust and reliable.

Injection Molding Prototyping: Material Selection Impact

Cost-Effectiveness of Injection Molding Prototyping in Product Lifecycle Management

Injection molding prototyping plays a pivotal role in the product development lifecycle, particularly when considering cost-effectiveness. By utilizing this method early in the design phase, companies can significantly reduce expenses associated with traditional prototyping techniques. Injection molding allows for high precision and repeatability, enabling designers to produce prototypes that closely reflect the final product.

This not only streamlines the design process but also minimizes the risk of costly revisions later on.

Moreover, the ability to create multiple iterations quickly and affordably means that organizations can gather valuable feedback earlier in the development process. This iterative approach helps in identifying potential design flaws and making necessary adjustments while still in the prototyping phase, thus preventing expensive production errors down the line.

Overall, integrating injection molding into product lifecycle management not only enhances efficiency but also contributes to a more effective allocation of resources, ensuring that budget constraints do not hinder innovation and product quality.

Real-World Success Stories: Impact of Injection Molding Prototyping on Innovation

Injection molding prototyping plays a pivotal role in driving innovation across various industries. The process allows companies to create high-quality prototypes quickly, which is essential when time is a factor in product development. For instance, annual competitions in sectors like biomedical engineering emphasize rapid prototyping and teamwork, showcasing how strict deadlines foster creativity and accountability. Such environments encourage participants to iterate designs swiftly, ultimately leading to innovative solutions that might not have emerged in a more traditional, less urgent setting.

One noteworthy example of the impact of injection molding prototyping can be seen in the realm of micromolding. This advanced technology continues to evolve, delivering precision and efficiency that are critical for the miniaturization of components in various fields. The ability to prototype using micromolding not only accelerates development timelines but also enhances product functionality. As businesses recognize the importance of swift prototyping, they gain a competitive edge in the market, demonstrating that effective product development relies heavily on utilizing advanced prototyping techniques like injection molding. This strategic approach is essential for bringing groundbreaking innovations to life.

Why Injection Molding Prototyping is Essential for Product Development Success

| Project Name | Industry | Prototyping Duration (Weeks) | Cost Savings (%) | Innovation Impact |

|---|---|---|---|---|

| Smart Home Device | Consumer Electronics | 4 | 25 | Enhanced User Experience |

| Medical Device Component | Healthcare | 6 | 30 | Compliance & Safety Improvement |

| Automotive Part | Automotive | 5 | 20 | Weight Reduction & Efficiency |

| Packaging Solution | Food & Beverage | 3 | 15 | Sustainability & Shelf Life |

Related Posts

-

Mastering Injection Molding Design: Tips for Reducing Production Costs and Enhancing Efficiency

-

5 Digital Tips for Effective Injection Molding Prototyping Success

-

The Future of Injection Mold Making: Innovative Techniques Transforming Manufacturing

-

Maximizing Efficiency: Key Advantages of Injection Molding in Modern Manufacturing

-

Exploring Injection Moulding Process Innovations at the 138th China Import and Export Fair 2025

-

How to Effectively Utilize Injection Molding Prototyping for Your Product Development