5 Tips for Mastering Precision Injection Techniques in Your Manufacturing Process

In today's highly competitive manufacturing landscape, the importance of mastering precision injection techniques cannot be overstated. According to a recent report by MarketsandMarkets, the global injection molding market is projected to reach USD 339.8 billion by 2026, driven by the increasing demand for high-quality, complex components across various industries.

In today's highly competitive manufacturing landscape, the importance of mastering precision injection techniques cannot be overstated. According to a recent report by MarketsandMarkets, the global injection molding market is projected to reach USD 339.8 billion by 2026, driven by the increasing demand for high-quality, complex components across various industries.

Precision injection molding plays a critical role in this growth, enabling manufacturers to produce intricate parts with minimal waste and enhanced efficiency. As companies seek to optimize their production processes and improve the quality of their products, mastering precision injection not only supports operational excellence but also drives innovation and sustainability.

This blog will explore five essential tips for manufacturers aiming to refine their precision injection techniques, ensuring they remain competitive in an ever-evolving market.

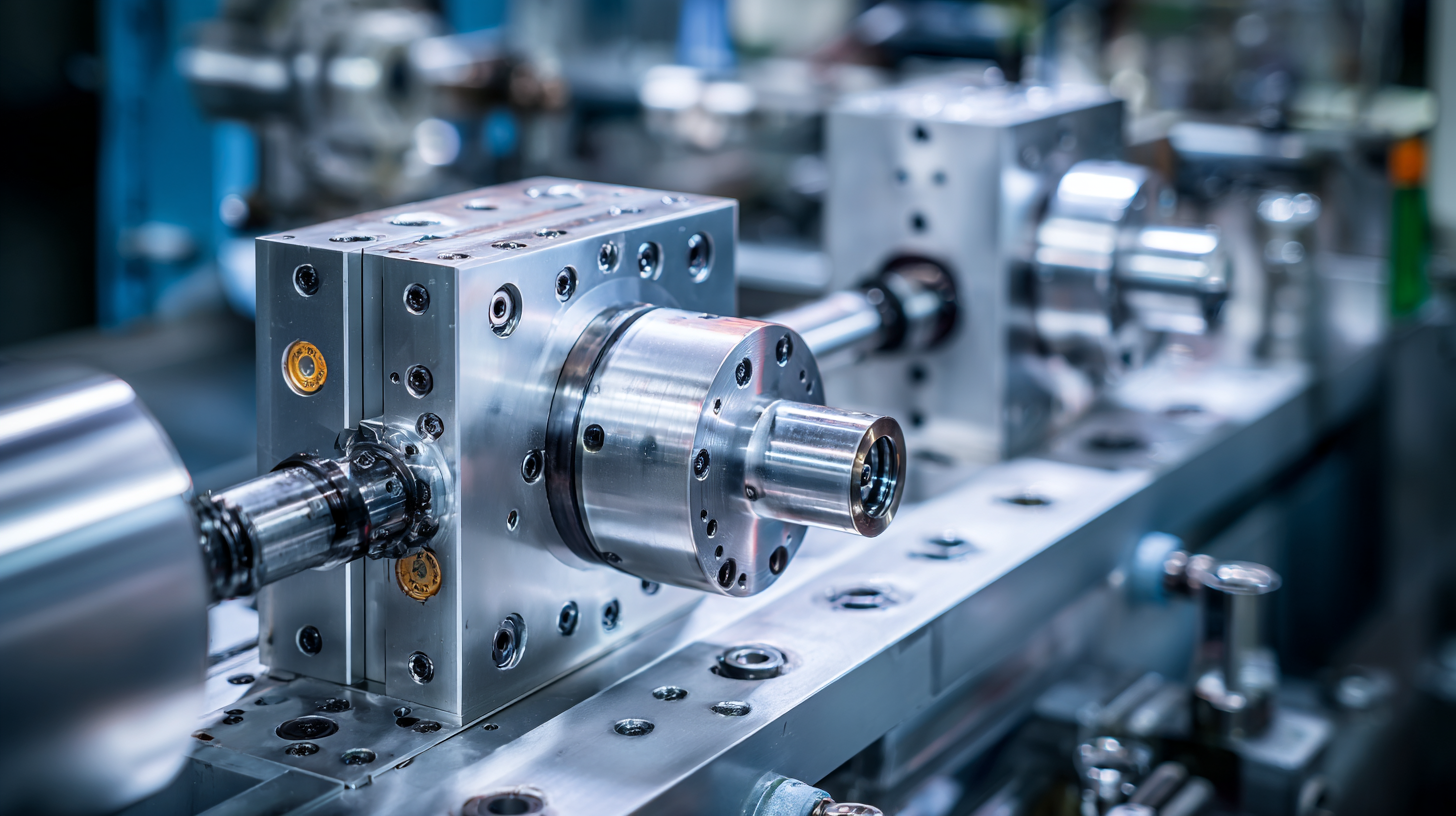

Understanding the Fundamentals of Precision Injection Techniques in Manufacturing

Precision injection techniques are essential in manufacturing, particularly in industries that demand high-quality components with tight tolerances. Understanding these fundamentals helps manufacturers improve their processes and achieve consistent results. A critical aspect of precision injection is the careful selection of materials and machine settings, which directly affect the final product's quality.

One effective tip for mastering precision injection techniques is to maintain strict control over temperature and pressure settings. Even slight variations can lead to defects, such as warping or incomplete filling. It's also crucial to regularly calibrate equipment to ensure optimal performance. Additionally, investing in advanced monitoring systems can help detect anomalies in real-time, allowing for quick adjustments to keep production on track.

Another important tip involves the design of molds. Molds should be engineered with precision to facilitate uniform flow of material and to minimize stress during the injection process. Using simulation software can aid in mold design by predicting potential issues before production begins. Finally, continual training and skill development for personnel involved in the injection process can significantly enhance overall precision, ensuring that every member of the team is well-versed in best practices and emerging technologies.

5 Tips for Mastering Precision Injection Techniques in Your Manufacturing Process

| Tip | Description | Expected Outcome |

|---|---|---|

| 1. Proper Material Selection | Choose materials that are compatible with the injection process to ensure quality production. | Increased product durability and reduced defects. |

| 2. Optimal Injection Pressure | Adjusting injection pressure to match material flow characteristics. | Improved filling efficiency and minimized voids. |

| 3. Temperature Control | Maintaining optimal temperatures throughout the injection phase. | Enhanced material consistency and better surface finish. |

| 4. Mold Design Considerations | Design molds that promote optimal flow and cooling. | Reduced cycle times and improved product quality. |

| 5. Regular Equipment Maintenance | Scheduled checks and maintenance of injection machines. | Consistency in production quality and reduced downtime. |

Key Metrics for Evaluating the Quality of Injection Molded Parts

Precision injection techniques are essential for ensuring the quality and reliability of molded parts in the manufacturing process. When evaluating the quality of injection molded parts, key metrics come into play. Dimensional accuracy stands out as a crucial criterion; with increasingly stringent tolerance levels, maintaining precise measurements is vital for the success of any production run. Implementing self-optimizing local mold temperature control can significantly reduce inline warpage, enhancing the overall quality of the finished products.

To master precision injection techniques, manufacturers should consider the following tips: First, it's imperative to regularly calibrate and maintain injection molding equipment to ensure consistent performance. Additionally, conducting thorough process simulations before actual production can help in identifying potential issues early on. Consistent training for operators on the nuances of injection processes can also lead to improved outcomes, enabling teams to adapt quickly to variations and enhance the production quality of injection molded parts.

Injection Molded Parts Quality Metrics

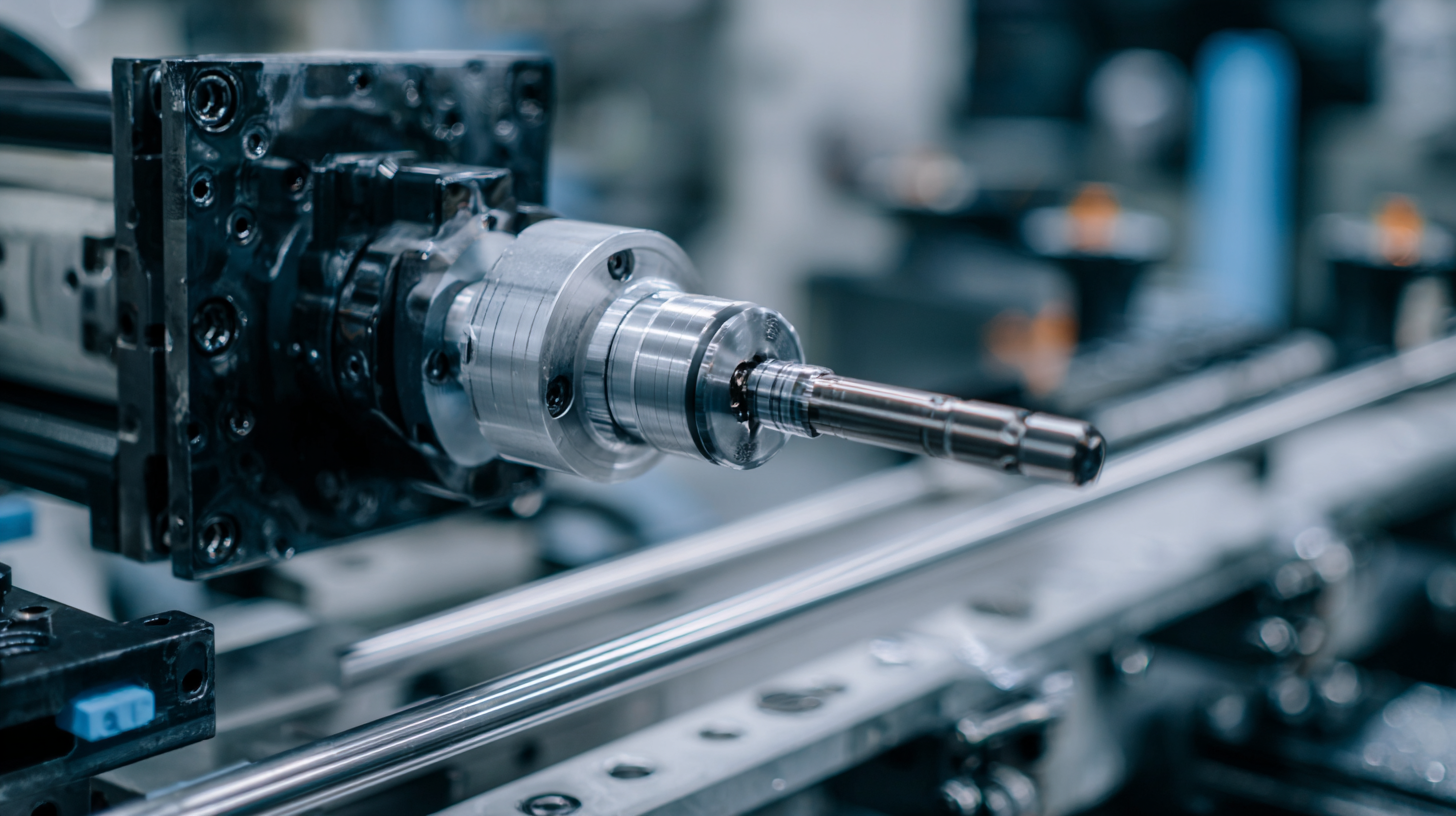

Innovative Technologies Enhancing Precision in Injection Molding Processes

In today's rapidly evolving manufacturing landscape, precision injection molding holds a central position, thanks to innovative technologies that enhance accuracy and efficiency. One of the groundbreaking advancements is the introduction of smart sensors. These sensors provide real-time data regarding temperature, pressure, and material flow, enabling manufacturers to make instant adjustments during the injection process. This proactive monitoring not only improves product quality but also reduces waste and minimizes downtime.

Another significant technological advancement is the use of advanced simulation software. These tools allow engineers to create detailed virtual models of the injection process, analyzing various parameters before actual production begins. By utilizing such simulations, manufacturers can optimize mold designs and predict potential issues, leading to a more streamlined production workflow. As a result, the integration of these innovative technologies is not just enhancing precision in injection molding but also paving the way for smarter and more sustainable manufacturing practices.

Common Challenges in Precision Injection Techniques and Solutions

Precision injection techniques are essential in manufacturing, particularly in industries such as automotive and medical device production, where exact specifications are crucial. However, companies often encounter common challenges that can hinder effectiveness. One prevalent issue is achieving uniform material flow, which can lead to inconsistencies in product quality. According to a 2022 report by the International Society of Plastics Engineers, approximately 30% of defects in molded parts are attributed to improper flow characteristics.

Another significant challenge is the maintenance of temperature control during the injection process, which directly impacts material properties and dimensional accuracy. The same report highlights that temperature variations can lead to a staggering 20% increase in defect rates. Implementing advanced control systems and regular maintenance can mitigate these effects. Furthermore, employee training in precision injection techniques is vital, as a skilled workforce can diagnose problems and adjust settings in real-time, reducing downtime and increasing overall production efficiency. Addressing these challenges is key to mastering precision injection techniques and optimizing manufacturing processes.

Real-World Case Studies: Success Stories in Precision Injection Manufacturing

In the world of precision injection manufacturing, real-world case studies highlight the tangible benefits of mastering injection techniques. One notable success story comes from a leading automotive component manufacturer that faced challenges with product consistency. By implementing advanced precision injection techniques, they were able to enhance their production efficiency and reduce waste by 30%. This transformation not only improved product quality but also significantly lowered operational costs, demonstrating the potential impact of precision manufacturing on the bottom line.

Another compelling case involves a medical device company that specialized in creating high-quality tools for surgical procedures. After adopting precision injection methods, they achieved unprecedented accuracy and repeatability, which are critical in the medical field. The results were twofold: improved patient safety and a marked increase in demand for their products. This success underscores the importance of innovation and the necessity of continuous improvement in injection molding techniques to remain competitive in today’s market. Such examples serve as benchmarks for other manufacturers aiming to optimize their processes and achieve similar success.

Related Posts

-

Unlocking Efficiency: The Key Benefits of Contract Injection Molding for Manufacturing Success

-

Understanding the Role of Precision Injection in Modern Manufacturing

-

Tailored Solutions for Rapid Prototyping Injection Molding: Driving Efficiency with Accurate Data Insights

-

Maximizing Efficiency: Key Advantages of Injection Molding in Modern Manufacturing

-

Innovative Injection Molding Applications That Redefine Manufacturing Standards

-

Innovative Solutions for Rapid Injection Molding Efficiency Optimization