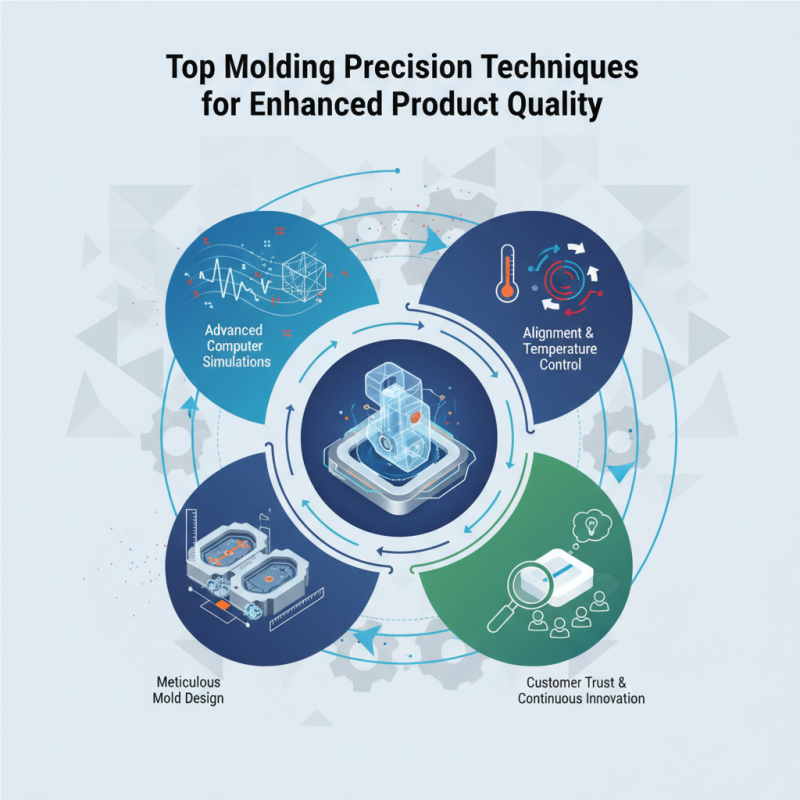

Top Molding Precision Techniques for Enhanced Product Quality?

In today's manufacturing landscape, molding precision plays a crucial role in enhancing product quality. The techniques adopted in the molding process directly impact the design and functionality of the final product. Companies strive for excellence, yet many face challenges in achieving perfect outcomes. Variations in material properties and environmental conditions can lead to inconsistencies.

Molding precision involves a range of techniques, from advanced computer simulations to meticulous mold design. These practices aim to minimize errors and maximize efficiency. Yet, there are moments when even the best processes yield imperfections. Mistakes can occur in alignment or temperature control, revealing areas for improvement. Reflecting on these issues is vital in the pursuit of perfection.

Ultimately, a commitment to molding precision not only improves product quality but also builds trust with customers. Focusing on detail-oriented techniques can lead to better results, but nothing is flawless. Manufacturers must continuously evaluate their methods. This ongoing reflection fosters innovation and leads to enhanced molding practices, paving the way for superior products.

Overview of Molding Precision Techniques in Manufacturing

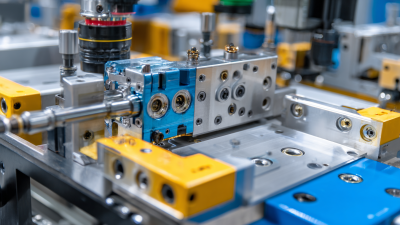

Molding precision techniques are crucial for achieving high product quality in manufacturing. These methods focus on tight tolerances and consistency, ensuring that every piece meets exact standards. Technologies such as injection molding, blow molding, and compression molding play a significant role. They shapes materials accurately, but not without challenges.

Creating flawless molds requires detailed planning and skilled labor. Many manufacturers find it difficult to maintain quality across large production runs. Issues such as temperature variations and material properties can lead to defects. Regular maintenance of equipment often gets overlooked, resulting in compromised precision. This can affect the overall efficiency and output quality.

Enhancing molding precision involves continuous improvement. Employing advanced technologies, like computer-aided design (CAD) and simulation software, can mitigate errors. However, relying solely on technology without proper training may lead to misunderstandings. Inspecting molds regularly is vital, yet many teams skip this step due to time constraints. A keen eye for detail is essential in this industry. Balancing efficiency and quality remains a constant challenge.

Importance of Precision in Product Quality and Performance

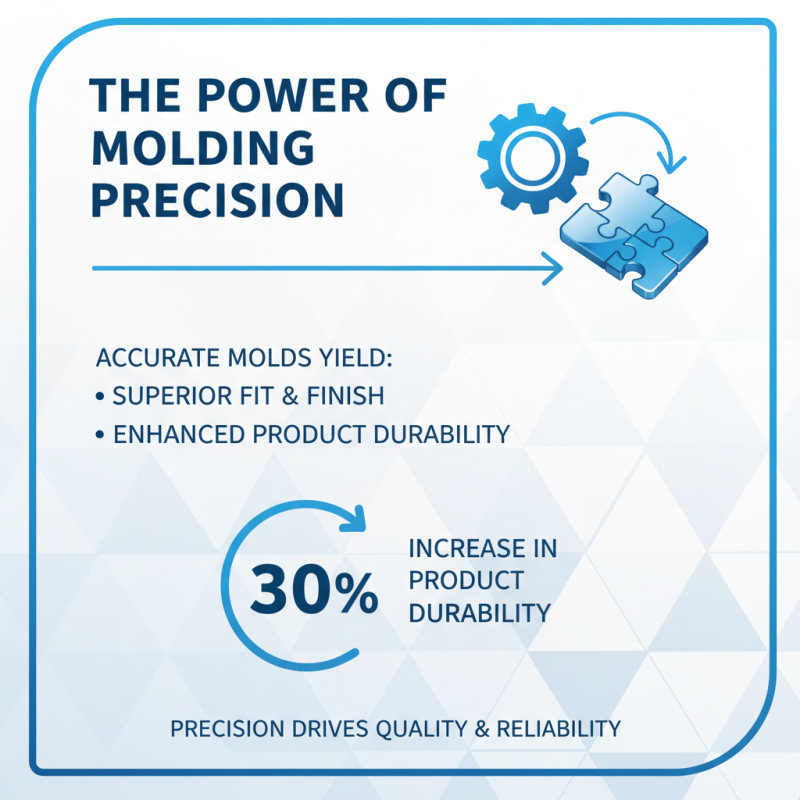

Precision plays a vital role in product quality and performance. In manufacturing, even a small deviation can lead to significant issues. According to a recent industry report, precision improvements can boost product reliability by 30%. This enhancement directly correlates to customer satisfaction and brand loyalty.

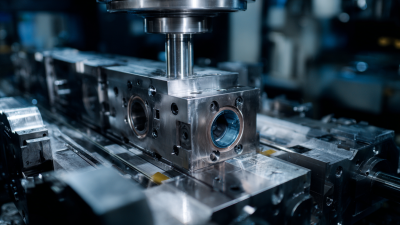

Modern molding techniques, such as CNC machining and laser cutting, emphasize precision. They enable manufacturers to attain tighter tolerances. However, implementing these techniques can be challenging. Many organizations struggle with the cost of advanced machinery and training. These barriers can hinder the potential for improved product quality. Furthermore, not addressing these areas can lead to inconsistency in production.

Data also shows that companies investing in precision technologies see a decrease in waste by 25%. This reduction is crucial for maintaining profitability. Yet, some firms overlook the importance of continuous precision training for staff. Neglecting this can create gaps in knowledge. Ultimately, focusing on precision not only enhances the product quality but also streamlines operational efficiency.

Key Techniques for Enhancing Molding Precision

Molding precision is crucial for product quality. Accurate molds lead to better fits and finishes. According to a recent industry report, improving molding precision can enhance product durability by 30%. This statistic underscores why manufacturers prioritize techniques that boost precision.

One effective method is the use of advanced simulation software. This technology can predict how materials will behave under various conditions. However, it can be expensive and requires skilled operators. Additionally, even with simulations, unexpected results can still occur during actual production runs. Continuous feedback loops can help identify these discrepancies and address them.

Another key technique is the implementation of high-resolution laser scanning. This can ensure molds maintain their desired dimensions over time. Yet, factors such as environmental conditions and tool wear can introduce variability. The challenge lies in consistently managing these elements to minimize errors. Failing to address them can lead to costly rework and waste. Ultimately, enhancing molding precision is a complex but vital endeavor for manufacturers.

Applications and Industries Benefiting from Precision Molding

Precision molding techniques are transforming several industries, significantly enhancing product quality. In the automotive sector, for instance, components made with precision techniques improve safety and performance. According to a recent industry report, companies utilizing advanced molding techniques have seen defect rates decrease by up to 30%. This data underscores how essential accuracy is in manufacturing.

In the medical device industry, precision molding is crucial. It allows for the creation of intricate designs that meet stringent regulatory standards. Reports indicate that 70% of medical device manufacturers are investing in precision molding to improve their product reliability. This approach minimizes the risk of failures in critical devices like surgical instruments. However, as with any technique, the challenge remains in ensuring consistent quality over time.

Electronics also benefit significantly from precision molding. High-quality cases and components are vital for protecting fragile internal parts. Manufacturers are facing pressure to balance speed and detail. A study showed that 65% of electronics companies struggle with this aspect. Maintaining precision while scaling production remains a point of reflection. Tracking defects in real-time is essential for continuous improvement in these sectors.

Future Trends in Molding Precision Technology

The future of molding precision technology is exciting yet complex. Advanced materials are changing the game. New polymers and composites provide lighter, stronger options. However, keeping consistency in production remains a challenge. Manufacturers must adapt to these shifts, which can lead to imperfections in the final product.

Automation plays a crucial role in improving precision. Robotic systems enhance accuracy in molding processes. Yet, human oversight is still necessary. Machines can fail. Errors in calibration can occur, leading to defective components. Finding the right balance between automation and human expertise is vital.

Data analytics is another emerging trend. By tracking production data, companies can identify flaws early. Integrating AI allows for real-time adjustments. However, reliance on technology can introduce complications. There's always the risk of overfitting models, which could skew results. The path ahead is filled with opportunities, but also demands critical reflection and adaptation.

Related Posts

-

Unlocking Efficiency: The Key Benefits of Contract Injection Molding for Manufacturing Success

-

Ultimate Guide to Achieving High Molding Precision in Manufacturing

-

Understanding the Role of Precision Injection in Modern Manufacturing

-

The Future of Injection Mold Making Innovations Driving Efficiency and Cost Savings in Manufacturing

-

Understanding US Injection Molding: Key Statistics and Trends Shaping the Industry in 2023

-

Understanding the Impact of Molding Precision on Sustainable Manufacturing Practices