Top 10 Tips for Optimizing Injection Mold Manufacturing Efficiency

In the fast-evolving world of manufacturing, achieving optimal efficiency in injection mold manufacturing is crucial for staying competitive. According to Dr. Emily Parker, a leading expert in the field and a professor at the Institute for Precision Engineering, "Maximizing efficiency in injection mold manufacturing not only reduces production costs but also significantly enhances product quality." Her insights underline the importance of refining processes and leveraging technology to streamline operations.

In the realm of injection mold manufacturing, every second counts. Manufacturers are constantly on the lookout for strategies that can lead to more effective production cycles, minimal waste, and superior end products. As industry demands evolve, the need for a strategic approach becomes increasingly prominent. By implementing targeted practices, companies can ensure they are not only meeting current market needs but also paving the way for future advancements in manufacturing processes.

This article will explore the top ten tips for optimizing injection mold manufacturing efficiency, drawing on contemporary insights and strategies that can be adopted by manufacturers seeking to enhance their operations in this critical sector. With a focus on both technical and managerial improvements, these tips can serve as a roadmap for companies aiming to elevate their production capabilities.

Understanding the Importance of Injection Mold Manufacturing Efficiency

Injection mold manufacturing efficiency is crucial for enhancing productivity, reducing costs, and ensuring the timely delivery of quality products in the competitive manufacturing landscape. According to a report published by the Plastics Industry Association, inefficient processes can lead to significant production setbacks, with downtime costing manufacturers an average of $200,000 annually per production line. By understanding the components that impact efficiency, companies can implement targeted strategies to optimize their operations.

Key factors influencing injection mold manufacturing efficiency include machine utilization, cycle time, and workforce training. A study from the Society of Plastics Engineers indicates that optimizing cycle time can lead to a reduction in production costs by up to 25%. Additionally, investing in employee training not only improves skill levels but also enhances problem-solving capabilities on the shop floor. Reports suggest that companies focusing on workforce development experience a 15% increase in efficiency and a notable reduction in waste, further underscoring the importance of a holistic approach to optimizing injection mold manufacturing processes.

Key Factors Affecting Injection Mold Production Efficiency

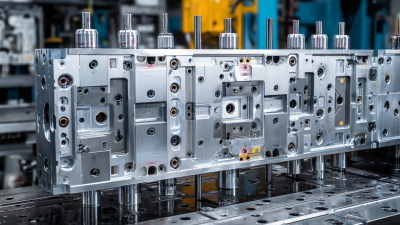

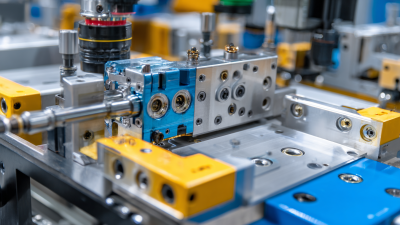

Optimizing injection mold manufacturing efficiency is essential for enhancing productivity and reducing costs. Several key factors significantly influence the overall production efficiency in this field. Firstly, the design and complexity of the mold itself play a crucial role. A well-optimized mold design not only minimizes production cycles but also facilitates easier maintenance and modifications. By incorporating advanced modeling techniques and simulations during the design phase, manufacturers can identify potential issues early on, streamlining the entire process.

In addition to mold design, the selection of materials and processing techniques is vital. Using high-quality materials can lead to improved durability and reduced wear, ultimately extending the lifespan of the mold. Furthermore, adopting innovative processing technologies, such as advanced cooling systems or automation, can significantly enhance cycle times. It is essential to continuously evaluate and update these factors to keep up with evolving industry standards.

Implementing preventive maintenance practices is another critical tip for boosting efficiency. Regular inspections and maintenance schedules can prevent unexpected breakdowns and costly downtimes. Additionally, investing in employee training ensures that team members are well-equipped to handle machinery effectively, leading to a smoother workflow. By focusing on these fundamental areas, manufacturers can achieve significant improvements in injection mold production efficiency.

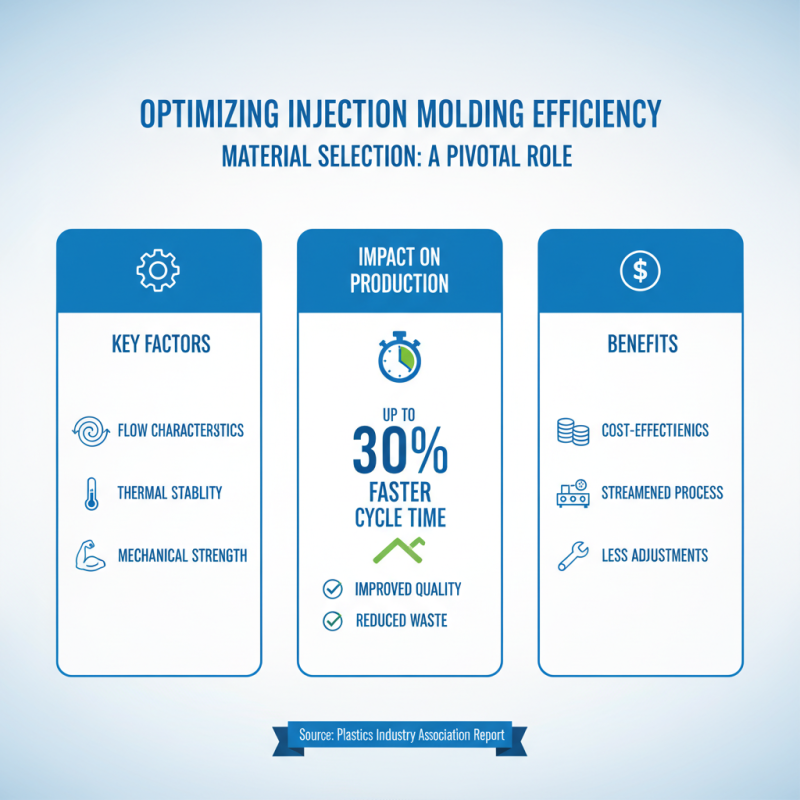

Best Practices for Material Selection in Injection Molding

When it comes to optimizing efficiency in injection molding, material selection plays a pivotal role that should not be overlooked. Different polymers offer varying properties that can significantly influence production speed, quality, and cost-effectiveness. According to a report by the Plastics Industry Association, the right material choice can enhance cycle time by up to 30%, resulting in a more streamlined manufacturing process. Factors such as flow characteristics, thermal stability, and mechanical strength must be considered to minimize waste and reduce the need for adjustments during the injection process.

Furthermore, the compatibility of the chosen material with the specific design and application is crucial. A study conducted by the Society of Plastics Engineers highlights that up to 60% of molding defects are attributable to improper material selection, leading to increased downtime and rework. To optimize manufacturing efficiency, it's essential to invest time in understanding the properties of various materials and how they align with the project requirements. Utilizing advanced simulation technologies can further aid in predicting performance outcomes, thus ensuring that manufacturers select materials that not only meet their economic goals but also contribute to operational excellence.

Enhancing Process Control Techniques for Better Outcomes

Enhancing process control techniques is essential for optimizing injection mold manufacturing efficiency. By employing advanced monitoring systems, manufacturers can gain real-time insights into the molding process. This allows for immediate adjustments to be made, reducing cycle times and minimizing defects. Implementing statistical process control (SPC) techniques enables teams to manage variations in production, ensuring that each part produced meets the required specifications and quality standards.

In addition, utilizing automation in the injection molding process can significantly improve overall efficiency. Automated systems facilitate precise control over parameters such as temperature, pressure, and injection speed, which are critical to achieving consistent results. Moreover, integrating machine learning algorithms can help predict potential issues before they arise, allowing for proactive measures to be taken. By enhancing these process control techniques, manufacturers not only improve productivity but also enhance product quality, leading to better outcomes overall in the injection molding industry.

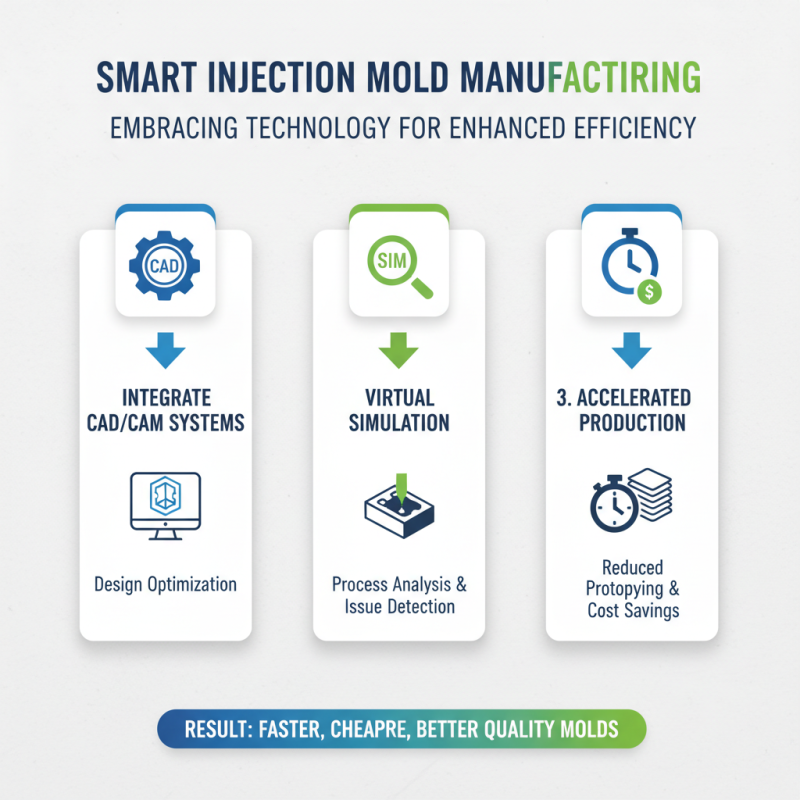

Utilizing Technology to Streamline Injection Mold Operations

Embracing technology is essential for enhancing the efficiency of injection mold manufacturing operations. One of the most effective strategies is integrating computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. These advanced technologies allow engineers to simulate the molding process, identify potential issues, and optimize designs before production begins. By utilizing virtual simulations, companies can reduce time spent on prototyping and make necessary adjustments, leading to significant cost savings and quicker turnaround times.

Moreover, implementing real-time data analytics can radically transform operational efficiency. By equipping machines with sensors and Internet of Things (IoT) capabilities, manufacturers can monitor performance metrics, maintenance needs, and production rates in real-time. This data-driven approach not only facilitates predictive maintenance, minimizing downtime but also allows for continuous process improvement. With the help of artificial intelligence (AI), organizations can analyze historical data to forecast demand and adapt production schedules accordingly, ensuring they meet market needs more effectively while optimizing their resources.

Related Posts

-

2025 Top 10 Trends in Injection Mold Making to Watch for Industry Growth and Innovation

-

The Future of Injection Mold Making Innovations Driving Efficiency and Cost Savings in Manufacturing

-

The Future of Injection Mold Making: Innovative Techniques Transforming Manufacturing

-

Mastering Injection Molding Design: Tips for Reducing Production Costs and Enhancing Efficiency

-

Why Injection Molding Prototyping is Essential for Product Development Success

-

Maximizing Efficiency: Key Advantages of Injection Molding in Modern Manufacturing