Top 10 FAQs About Injection Molding: What You Need to Know

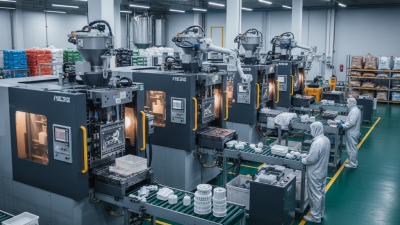

Injection molding is a transformative manufacturing process that plays a pivotal role in producing a wide array of plastic products, from everyday items to complex components used in various industries. As the demand for precise and efficient production techniques continues to grow, understanding the intricacies of injection molding has become essential for both manufacturers and consumers alike. This article aims to address the most frequently asked questions about injection molding, shedding light on the fundamentals and practical applications of this technology.

In the following sections, we will explore the key aspects of injection molding, including its operational mechanics, materials used, and the benefits it offers in terms of scalability and product quality. By answering common inquiries, we hope to provide clarity on how injection molding can meet diverse manufacturing needs and the considerations that should be taken into account for successful implementation. Whether you are an industry professional or simply curious about the process, this guide will equip you with the knowledge necessary to navigate the world of injection molding effectively.

What is Injection Molding and How Does It Work?

Injection molding is a widely utilized manufacturing process that involves the creation of parts by injecting molten material into a mold. This technique is predominantly employed for producing plastic components, but it can also be adapted for metals and glass. The process begins with the melting of plastic pellets, which are then forced into the mold cavity under high pressure. Once the material cools and solidifies, the mold opens, and the newly formed part is ejected. According to a report by MarketsandMarkets, the global injection molding market is expected to reach USD 394.32 billion by 2027, reflecting a strong demand for efficient and cost-effective manufacturing solutions.

One of the key advantages of injection molding is its ability to produce high volumes of parts with tight tolerances and excellent repeatability. This process is also highly efficient, with cycle times ranging from a few seconds to a couple of minutes, depending on the complexity and size of the part. Furthermore, the flexibility in material selection allows manufacturers to choose from a wide range of thermoplastics and thermosetting polymers, catering to various industry needs, including automotive, consumer goods, and medical devices. A study by Grand View Research highlights that the increasing demand for lightweight and durable materials in the automotive sector is a significant driver of the growth in injection molding applications.

Top 10 FAQs About Injection Molding: What You Need to Know

| FAQ Number | Question | Answer | Key Considerations |

|---|---|---|---|

| 1 | What is injection molding? | A manufacturing process for producing parts by injecting material into a mold. | Material type and mold design are critical. |

| 2 | What materials can be used? | Common materials include plastics, metals, and ceramics. | Choose based on the desired properties of the final product. |

| 3 | How long does the process take? | Cycle times can range from a few seconds to several minutes. | Dependent on part size and complexity. |

| 4 | What are the benefits of injection molding? | High production efficiency, low waste, and consistent quality. | Requires initial investment for mold creation. |

| 5 | What is the typical lead time? | Lead time varies based on design complexity and production volume. | Planning ahead is crucial for meeting deadlines. |

| 6 | Can complex shapes be achieved? | Yes, injection molding can create intricate shapes. | Mold designs need to accommodate complex features. |

| 7 | What is the cost per part? | Cost varies based on material, design, and quantity. | Economies of scale apply; larger runs reduce cost per part. |

| 8 | How is quality controlled? | Quality control includes inspections and testing during production. | Regular audits can help maintain quality standards. |

| 9 | What industries use injection molding? | Widely used in automotive, consumer goods, and electronics. | Adaptable for a variety of applications. |

| 10 | What is the environmental impact? | Can be optimized for sustainability through recycling and material choices. | Considerations for sourcing and disposal are key. |

Common Materials Used in Injection Molding Processes

Injection molding is a widely used manufacturing process known for its efficiency and versatility in producing plastic parts. The common materials used in this process can significantly influence the performance, cost, and durability of the final products. Among the most popular materials are thermoplastics, thermosetting plastics, and elastomers. According to a 2021 report by Grand View Research, thermoplastics accounted for over 70% of the global injection molding materials market, driven by their recyclability and ease of processing.

Polypropylene (PP) and polystyrene (PS) are two thermoplastics routinely chosen for their excellent balance of cost, strength, and moldability, making them ideal for a range of applications from industrial components to consumer goods. On the other hand, thermosetting plastics, like epoxy and phenolic resins, offer superior mechanical properties and thermal stability, making them suitable for applications requiring rigidity and heat resistance. The increasing adoption of bioplastics, projected to grow from 10% to 30% of the market by 2025, indicates a shift towards more sustainable options without compromising performance.

Additionally, elastomers like thermoplastic elastomers (TPE) are increasingly favored for applications requiring flexibility and elasticity. Their unique properties allow manufacturers to create parts that can withstand varying degrees of temperature and stress, making them popular in industries such as automotive and healthcare. As the injection molding industry continues to evolve, the choice of materials will play a crucial role in driving innovation and meeting sustainability goals.

Key Advantages of Using Injection Molding for Production

Injection molding is a manufacturing process that offers significant advantages for production, making it a popular choice across various industries. One of its primary benefits is efficiency; the process allows for the rapid production of large quantities of identical parts with minimal labor costs. This is particularly advantageous for companies looking to scale their operations quickly or meet high demand without sacrificing quality. Additionally, injection molding enables intricate designs that might be difficult or impossible with other methods, providing designers with the flexibility to create complex geometries.

When considering injection molding for production, it's essential to keep a few tips in mind. First, proper material selection is crucial—different polymers can influence the durability and functionality of the final product. Secondly, investing in high-quality molds can significantly improve the efficiency of the production process and reduce the likelihood of defects. Finally, maintaining a close relationship with your injection molding provider will help ensure that any potential issues are resolved quickly, thus minimizing downtime and maximizing output.

Overall, leveraging the advantages of injection molding can lead to superior product quality and greater operational efficiency, making it an ideal choice for many production needs.

Top 10 FAQs About Injection Molding

This chart illustrates the key advantages of using injection molding for production, highlighting factors such as cost efficiency, production speed, and quality consistency.

Typical Applications and Industries Utilizing Injection Molding

Injection molding is a widely used manufacturing process, particularly in industries that require high-efficiency production of plastic parts. According to recent industry reports, the global injection molding market was valued at approximately $200 billion in 2022 and is expected to grow significantly in the coming years. This technology finds applications in various sectors, including automotive, healthcare, consumer goods, and electronic devices, owing to its ability to produce intricate designs and high-volume outputs.

In the automotive industry, for instance, injection molding is employed to create components such as dashboard assemblies, door panels, and other interior fittings. The lightweight nature of injected parts helps manufacturers reduce the overall weight of vehicles, thereby improving fuel efficiency and compliance with environmental regulations. Meanwhile, the healthcare sector increasingly leverages injection molding to produce precise medical devices and disposable equipment, ensuring high levels of sterility and performance reliability. Notably, the growing demand for sustainable manufacturing practices is prompting industries to adopt advanced injection molding techniques that utilize recycled materials and enhance energy efficiency, further solidifying this method’s pivotal role across multiple sectors.

Frequently Asked Questions About Injection Molding Costs and Timeframes

Injection molding is a widely used manufacturing process that involves injecting molten material into a mold to create various plastic parts. One of the most common questions regarding this process is about the associated costs. Typically, the initial setup for injection molding can require a significant investment, with average tooling costs ranging from $5,000 to $100,000 depending on complexity and size. However, the cost per part significantly decreases with higher production volumes, making injection molding an efficient choice for large-scale manufacturing.

Timeframes for injection molding projects often depend on the specifics of design, tooling, and production runs. According to industry reports, the average lead time for developing a new injection mold can take anywhere from four to twelve weeks. Once production starts, however, the cycle times can be remarkably swift, averaging just 15 to 30 seconds per cycle for smaller parts. This efficiency plays a crucial role in meeting tight deadlines and ensuring that products can reach the market promptly, a vital factor for many companies looking to maintain a competitive edge.

Related Posts

-

Maximizing Efficiency: Key Advantages of Injection Molding in Modern Manufacturing

-

Innovative Injection Molding Applications That Redefine Manufacturing Standards

-

5 Essential Tips to Maximize Efficiency in Injection Molding Processes

-

10 Best Injection Molding Techniques for Maximizing Efficiency in Production

-

Exploring the Future of US Injection Molding: Innovations and Industry Trends

-

Ultimate Guide to Precision Injection Molding for Global Buyers in 2023